TITAL GmbH, the titanium and aluminum investment casting specialist in Bestwig, received qualification approvals from Airbus France for the production of several structural parts for the A380. TITAL now delivers three separate titanium investment casting ribs for the pylons – the connection between the engine and the wing – of the 500 passenger mega-airliner. The TITAL foundry based in the Sauerland area produces pylon parts for both engine versions of the A 380, namely the Trent 900 from Rolls Royce and the GP7200 from Engine Alliance. In optical terms these ribs remind you of window frames. TITAL casts these ribs, finishes them completely and delivers them ready for assembly to the Airbus plant in St. Eloi (France). These titanium castings which are designed to bear static and dynamic stresses and are resistant to material fatigue will now go into full production. According to TITAL GmbH, Airbus France is scheduled to produce and deliver three A380 aircrafts per month.

As the ribs must bear special dynamic stresses in practical use, these parts must survive multiple levels of fatigue testing to prove their stress capabilities. These tests are administered by independent testing laboratories certified to international standards. Material fatigue develops when a part is permanently exposed to dynamic strains such as multiple oscillations. As a consequence, these parts must prove their fatigue strength under extreme oscillation stresses. Moreover, the crack growth propagation strength is another important criterion. It provides information on the degree to which the part encounters a crack.

A positive evaluation by external testing laboratories is an essential criterion for the order from Airbus. Berthold Busch, Head of quality management at TITAL explains: "Without a certificate from the testing laboratories, Airbus would not accept these parts." There is only a small number of companies in the world able to produce this type of quality.

With this qualification TITAL has further strengthened its position as a strategic supplier to Airbus. Philipp Jerusalem, Director Sales & Marketing at TITAL comments: "Airbus France plays an important role for us. We started working with this customer in 2005, but have already realized higher sales than with Airbus Germany even though the German relationship already exists more than 30 years." The parts have dimensions of approximately 890x640x90 mm (35x25x3.5 inches) and 690x590x130 mm (27x23x5 inches) respectively and serve as a basis for the primary structure of the pylon. Until now TITAL has only supplied castings for the secondary structure of the aircraft (e. g. fairings and covers).

All the supply pipelines run through the pylons, and are among others responsible for engine controls. The A380 has four engines, supplied by Rolls Royce (type Trent 900) or Engine Alliance (type GP7200).

Currently, 244 aircrafts of the A380 have been sold. This under-wing aircraft is the largest civil aircraft ever produced in series-production. The first aircraft was delivered to Singapore Airlines on October 15, 2007 in Toulouse. The first passenger flight took place on October 25, 2007.

| Contact details from our directory: | |

| TITAL GmbH | Engine Parts, Metal & Alloy Castings, Aircraft Structural Components, Aluminium, Engine Pylons |

| Airbus S.A.S. | Airframer |

| Related aircraft programs: |

| Airbus A380 |

| Related directory sectors: |

| Metals |

| Engine Components |

Weekly news by email:

See the latest Bulletin, and sign up free‑of‑charge for future editions.

Textron Systems supports Kaman in advancing Kargo UAV technology

Airbus finalises its acquisition of Aerovel and its UAS Flexrotor

Joby progresses flight test programme

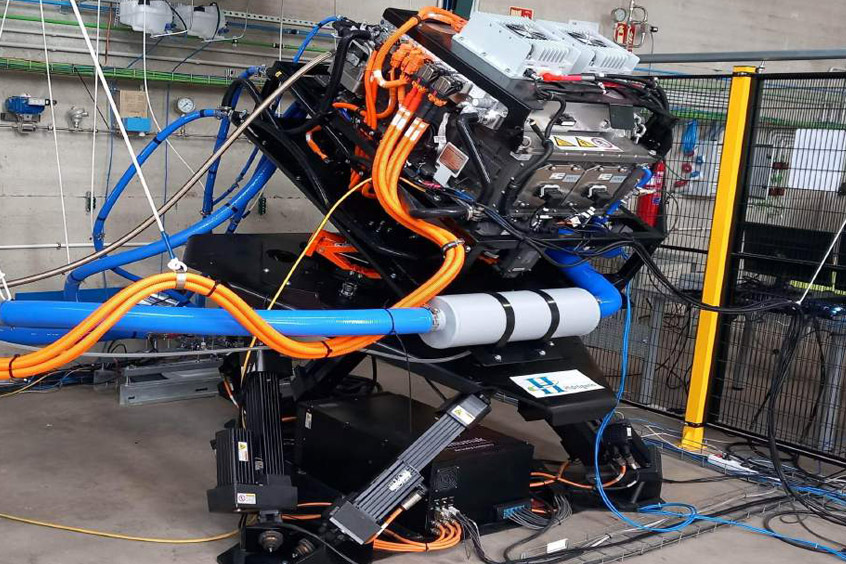

Airbus Upnext sources hydrogen fuel cell for aircraft APU tests