PRESS RELEASE

Issued by: Evektor-Aerotechnik, a.s.

The prototype of the new airplane EV-55M made its first take-off from Kunovice airport in the Czech Republic today. The airplane crew consisted of Evektor test pilot Josef Charvát and military pilot Major Ji?í Hána. The take-off took place at 10:55 a.m. of local time and took 30 minutes. During the flight the EV-55 reach the speed of 125 kts and the altitude of 3500 ft. "The airplane behaved exactly as we supposed – it was easily controllable and promptly reacted to the control interventions", stated Josef Charvát.

The EV-55M is a military variant of the multi-purpose airplane EV-55 Outback which is conceived as a high-wing, twin- engine, turboprop airplane for transportation of 9 - 14 passengers or 1824 kg cargo. The airplane has the most spacious cabin for passengers and cargo in its category with the total volume of 12.5 m3 and its cruising speed reaches 220 kts at 100 flight level. Technical parameters of this airplane predestinate it for operation from short, unpaved runways, possibly from high altitude airports. High productivity and low costs of operation and maintenance represent a high utility value of the EV-55 Outback which can be used by aircraft operators all over the world. The airplane is designed especially for operators from the countries of South America, Africa and Asia with underdeveloped transport infrastructure. Among other very promising customers are companies from the United States, Brazil, Russia, India, China and Australia. The EV-55 objective is replacement of already obsolete twin-engine piston airplanes with capacity for 6 – 9 passengers and it wants to be a successful competitor for single-engine turboprop airplanes.

The EV-55 airplane will be offered in 3 versions of cabin interior arrangement: version for passenger transport, version for cargo transport and combined version (combi version) having space for cargo located in the front part of the cabin and passenger seats in the rear part. The time needed for conversion of the cabin interior between individual versions should not exceed 20 minutes.

This airplane project was initiated by Evektor company and Association of Aircraft Manufacturers in the Czech Republic in 2004. It was followed by establishment of the consortium composed of Czech aircraft industry companies and led by Evektor company. The project was, since the very beginning, financially supported by the Ministry of Industry and Trade of the Czech Republic in form of a grant.

The consortium members are the following companies and organizations: Evektor spol. s r.o.; Evektor-Aerotechnik a.s.; AERO Vodochody a.s.; Alucast s.r.o.; Avia Propeller; Jihlavan a.s.; Jihostroj a.s.; MESIT p?ístroje spol. s r.o.; Mikrotechna Praha a.s.; PBS Velká Bíte? a.s.; SVÚM a.s.; TEAZ s.r.o, Technometra Radotín a.s.; ÚJV ?e? a.s.; UNIS a.s.; Aircraft Institute of VUT in Brno; VR Group a.s. and VZLÚ a.s.

Evektor company was founded in 1991 and belongs among the leading design and development offices in the Czech Republic. It deals with design and development above all in the area of automotive and aircraft industry. The airplane developed by Evektor company include small airplanes EuroStar and SportStar designed for leisure-time flying, four- seat airplane VUT100 Cobra and the multi-purpose airplane EV-55 Outback.

Evektor management shares this success with hundreds of employees, friends and partners, who had been working to make this flight happened. Having done the maiden flight Evektor is confident of this new aircraft future especially combined with the great interest potential customers worldwide.

| Contact details from our directory: | |

| Evektor-Aerotechnik, a.s. | Airframer |

| Related aircraft programs: |

| Evektor EV-55 Outback |

Weekly news by email:

See the latest Bulletin, and sign up free‑of‑charge for future editions.

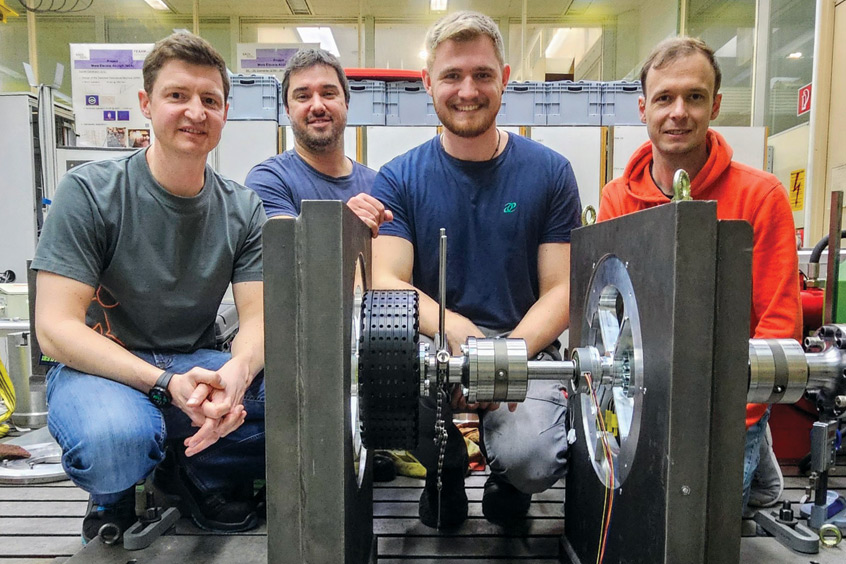

Vaeridion completes first functional validation of multi-engine propulsion concept

Opening of US R&D hub signals next development phase for Heart hybrid

Gulfstream G700 earns EASA certification