High-torque cutting performance with hard aerospace alloys has produced an order for four MAG large-part HMC 1600's to modernize the track-and-beam line at Boeing's Portland center for complex machining. Equipped with MAG's new T-Rex high-torque spindle, the HMC 1600 performed spectacularly in a cutting test highlighting its 2600 Nm (1918 lb-ft) torque and 42.3 kN (9,500 lb) cutting thrust. Combined with a chassis of ductile and cast-iron components, the T-Rex-equipped HMC 1600 delivers the stiffness and vibration damping needed for heavy, chatter-free cuts on titanium 5553, Inconel and Carpenter 465, commonly used by Boeing. Phase one for modernizing the track-and-beam line will start with two MAG 4-axis and two 5-axis machines to be installed starting August 2012. The new machines will replace existing systems, allowing the plant to produce more parts with higher accuracy, in greater variety, with less time and cost, helping to meet demand for Next-Generation 737 aircraft.

"Boeing's Portland machining operation sets the benchmark for hard-metal removal rates in the aerospace industry, so the bar is set high when they are considering new equipment to upgrade capabilities," said Chip Storie, MAG Executive Vice President, Aerospace. "Our T-Rex-equipped HMC 1600 put on an impressive demonstration for Boeing that highlighted its stiffness, power, agility and accuracy while cutting Carpenter 465 stainless steel hardened to 50-52 Rc. With tooling similar to Boeing's, the T-Rex spindle delivered triple the metal removal rates over Boeing's current machining technology, proving it can take this elite facility to a new level of performance and efficiency."

MAG's modular HMC Series is engineered for high-precision, high-productivity machining of large hard-metal components for aerospace, power generation, pump, valve, and off-road equipment. Designed for extreme application flexibility, the machine offers maximum 3000 mm (118 in) work-zone swing, and 14,000 kg (30,800 lb) pallet load capacity. Major machine components, including the X-bed, Z-bed and column, are cast ductile iron, with pallets up to 1600 x 2000 mm, headstock and rotary table housings of gray cast iron. The 360,000-position full-contouring rotary table provides a rigid work platform, while a rugged worm gear drive with clamp securely holds axis position. Rotary table positioning accuracy is 10 arc seconds, repeatable to 5 arc seconds. Positioning accuracy of the tilt-spindle is 4 arc seconds, repeatable to 2 arc seconds.

Eight spindle options include: 6000 and 8000 rpm/46 kW (61.6 hp) tilt-spindles with +90/-120 degree A-axis travel; a 10,000 rpm/46 kW (62 hp) spindle; high-speed 24,000 rpm spindle; T-Rex high-torque 2600 Nm/80 kW (1918 ft lb) spindle and two live spindles (110 or 130 mm diameter). The high-torque T-Rex spindle is specially engineered for hard-metal cutting, while the live spindles extend W-axis reach by up to 800 mm (31.5 in), enabling deep cavity milling to high precision with shorter, more rigid tools. Standard on the live spindle, MAG's exclusive Z-axis thermal compensation system dynamically offsets spindle growth to maintain correct axial position regardless of spindle temperature.

Meeting industry needs for tighter part tolerances and greater machining accuracies, the HMC Series comes standard with linear scale feedback in X, Y and Z axes, providing 8 micron (0.0003 in) positioning accuracy and 5 micron (0.0002 in) repeatability. Heavy-duty hardened and ground roller guide ways enable a rapid traverse rate of up to 40 m/min (1575 ipm) with high acc/dec rates, double the load capacity, and nearly 10 times the wear life of ball-type ways. The full work zone enclosure is pre-engineered to provide a clean machining environment and includes a doorway for operator access with walkway/platform inside.

The HMC 1600 is one of MAG's new modular machine designs for heavy metal cutting of large parts. It is available with optional MQC (Minimum Quantity Cryogenics) and MQL (Minimum Quantity Lubrication). Other recent aerospace machine introductions include the FTR AutoDrill for processing large, high-value aerostructures; large-part 5-axis gantry mills; and vertical precision mill and trim (PMT) systems. The highly configurable PMT is engineered for high traverse and acc/dec rates. Its patent-pending vacuum system makes it ideal for high-velocity milling, trimming and drilling of post-cure cutouts, wood, foam, composite, aluminum and titanium structures.

| Contact details from our directory: | |

| Fives Machining Systems, Inc. | Composite Manufacturing Supplies, Boring Equipment, Lathes, Machining Systems, Cutting Equipment, Cutting Tools, Composite Tape Lay-down, Grinding, Laminating Equipment, Gantries, Drilling Equipment, Routing, Milling, Numeric Control Equipment, Materials Handling Equipment, Systems Integration |

| Boeing Commercial Airplanes | Airframer |

| Related directory sectors: |

| Production Equipment |

| Machining |

Weekly news by email:

See the latest Bulletin, and sign up free‑of‑charge for future editions.

Textron Systems supports Kaman in advancing Kargo UAV technology

Airbus finalises its acquisition of Aerovel and its UAS Flexrotor

Joby progresses flight test programme

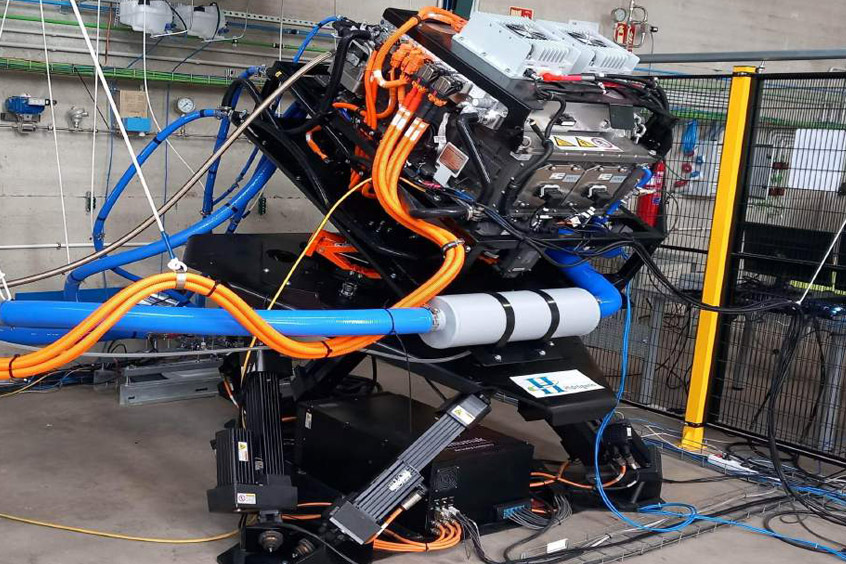

Airbus Upnext sources hydrogen fuel cell for aircraft APU tests