Rolls-Royce, the global power systems company, today marked the beginning of construction of its new advanced aerospace disc manufacturing facility with a groundbreaking ceremony conducted by Secretary of State for Business, Innovation and Skills, RT Hon. Vince Cable MP.

When fully operational, the facility at the Radial Business Park in Washington, Tyne and Wear will have capacity to manufacture over 2,000 fan and turbine discs a year. Fan Discs and Turbine Discs are at the heart of the engine, operating at high stress in extreme conditions providing the engine's thrust. They provide the power for a wide range of aircraft including the Boeing 787 Dreamliner, the Airbus A380 and the Eurofighter Typhoon.

The Business Secretary said: "The new Rolls-Royce advanced aerospace disc manufacturing plant will further strengthen the UK's position as an aerospace leader, and underpins the company's ongoing commitment to the North East and its workforce.

"As I recently set out in our industrial strategy, Government and business must work together for long term economic growth. This facility is a clear example of how business and Government is doing just that through the Aerospace Growth Partnership."

Alain Michaelis, Rolls-Royce Deputy Chief Operating Officer and President of the Gas Turbine Supply Chain said: "We are pleased to begin construction on this important new facility which will use some of the most advanced manufacturing techniques to produce high-tech aero engine components to power the most advanced aircraft operating today. Rolls-Royce continues to invest for future growth. In the last five years we have invested over £950 million in the UK in new and existing facilities to ensure we maintain our competitive edge."

The approximately 20,000m2 disc manufacturing facility is expected to begin production in late 2013. The manufacturing techniques which will be used at the facility have been developed at the Advanced Manufacturing Research Centre (AMRC) in Rotherham. The AMRC is part of a network of research centres which aim to work with businesses to apply university research to accelerate the commercialisation of new and emerging manufacturing technologies.

At the front of the engine the fan disc holds the fan blades. There are typically 20 in each engine. They rotate about 2,700 times per minute and move 1.25 tonnes of air per second, the equivalent of the volume of air in a squash court. The fan discs remain in service for over 20 years.

The turbine discs hold blades in the hottest part of the engine where the operating conditions are at their most severe. This requires use of some of the strongest materials available, made from refined powders specially processed and machined to the accuracy of a fraction of the thickness of a human hair. The blades that these discs hold each generate the power of a Formula One car and operate in temperatures several hundred degrees above their melting point. They are cooled by air ducted through the discs and use heat resistant coatings.

| Contact details from our directory: | |

| Rolls-Royce plc Civil Aerospace | Turbofan Engines, Additive Manufacturing, Ceramic |

| Related aircraft programs: |

| Eurofighter Typhoon |

| Boeing 787 Dreamliner |

| Airbus A380 |

| Related directory sectors: |

| Engines |

Weekly news by email:

See the latest Bulletin, and sign up free‑of‑charge for future editions.

Textron Systems supports Kaman in advancing Kargo UAV technology

Airbus finalises its acquisition of Aerovel and its UAS Flexrotor

Joby progresses flight test programme

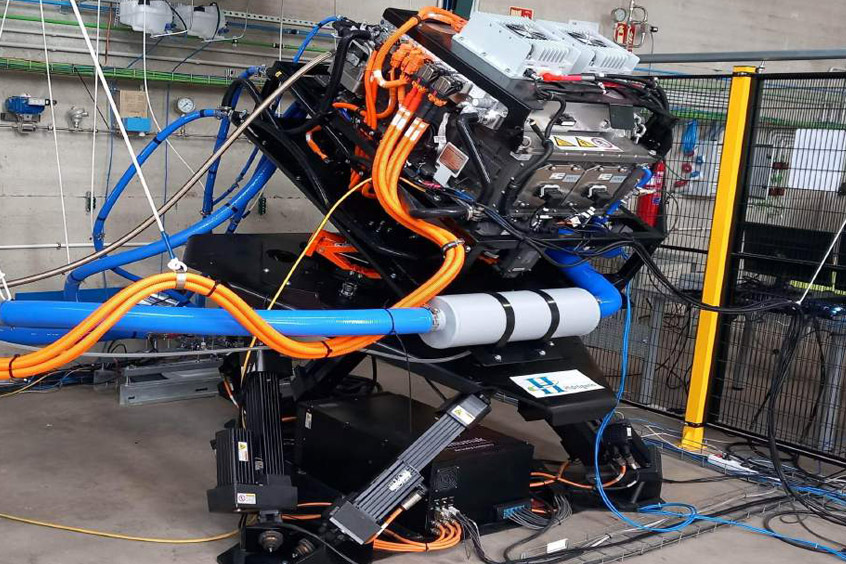

Airbus Upnext sources hydrogen fuel cell for aircraft APU tests