AgustaWestland, a Finmeccanica Company, today unveiled its "Project Zero" tilt rotor technology demonstrator, giving an insight into what advanced rotorcraft of the future may look like. This, however, is no paper study. The technology demonstrator was designed and built in less than 6 months and has already secretly flown several times in 2011 and 2012, demonstrating AgustaWestland's advanced rotorcraft technology.

The tilt rotor technology demonstrator is completely electric powered; designed to hover like a helicopter and convert to a fixed wing aircraft in forward flight thanks to its two integrated rotors which can be tilted through more than 90 degrees. The demonstrator performed its first unmanned tethered flight in June 2011 at AgustaWestland's Cascina Costa facility in Italy and has since performed untethered hovering flights inside a secured area.

Daniele Romiti, AgustaWestland's CEO, said "The 'Project Zero' technology demonstrator program brings together many of the advanced technologies AgustaWestland has been researching in recent years and demonstrates our strong technological base from which we will develop new products to meet the needs of our customers in the future. We strongly believe in the tilt rotor concept as the future of high speed rotorcraft flight as it offers much greater speed and range than compound helicopter technology."

"This is a wonderful achievement of the AgustaWestland Advanced Concepts Group. A team of passionate and brilliant engineers worked extremely hard in a secure facility to conceive, design, build and test this technology demonstrator in an exceptionally short period of time," said Dr. James Wang, Vice President of Research and Technology at AgustaWestland. "This group lives to dream, and if it can be dreamed, it can be built. The team did not just build an electric powered airplane or helicopter; that would have been too easy. They went all out and built a twin rotor electric tiltrotor with no transmission or swashplates."

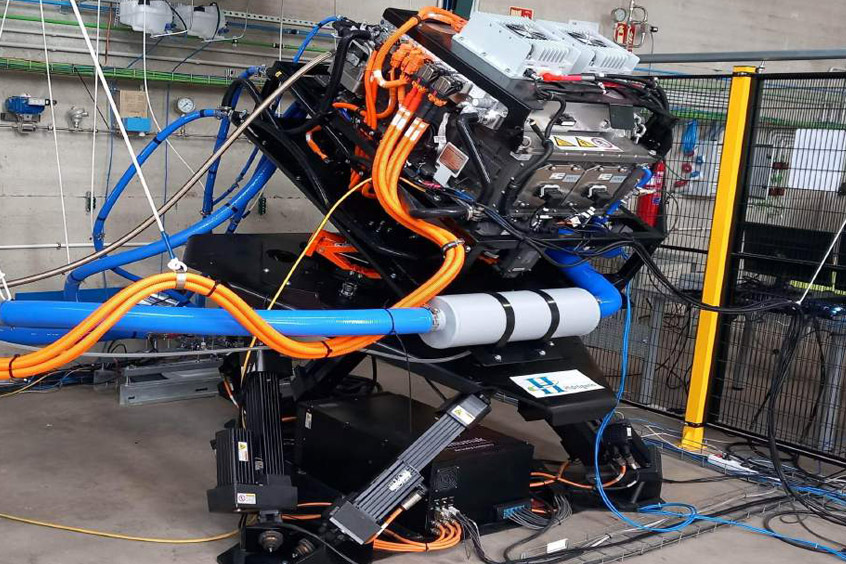

The demonstrator's rotors are driven by advanced electric motors powered by rechargeable batteries; future hybrid solutions have also been investigated using a diesel engine to drive a generator. All of the aircraft control systems, flight control and landing gear actuators are electrically powered, removing the need for any hydraulic system.

During cruise, the wings will provide most of the lift, with the blended fuselage and shroud also making a contribution. 'Project Zero' has been designed with detachable outer wings for missions that will be performed primarily in helicopter mode. Elevons provide pitch and roll control in forward flight while the V-tail provides longitudinal stability. The aircraft has very low noise and thermal signature in flight and does not require oxygen, thereby permitting it to fly at altitude or in heavily polluted conditions, such as volcanic eruptions.

The demonstrator's rotors when on the ground can be tilted forward and the aircraft pointed into wind to allow the rotors to windmill and recharge the aircraft's electrical storage device. The electrical drive system also has the advantage that it does away with the complex and heavy transmission system required by conventional rotorcraft.

The 'Project Zero' technology demonstrator programme is being entirely funded by AgustaWestland as part of its ongoing research and development activities.

| Contact details from our directory: | |

| Leonardo Helicopters | Airframer |

Weekly news by email:

See the latest Bulletin, and sign up free‑of‑charge for future editions.

Textron Systems supports Kaman in advancing Kargo UAV technology

Airbus finalises its acquisition of Aerovel and its UAS Flexrotor

Joby progresses flight test programme

Airbus Upnext sources hydrogen fuel cell for aircraft APU tests