At its facility in Lindenberg (Germany), Liebherr-Aerospace Lindenberg GmbH recently put into operation a new 260 m2 center for machining titanium parts - hydraulic valve blocks for the electric back-up hydraulic actuator (EBHA) of the A380 program and housings for filter pack units for the Eurofighter. In the future, components for new aircraft programs will also be produced there. The machining center includes a shelf magazine accommodating 80 pallets and an external tool storage and distribution system for 700 tools. The investment volume totals approx. € 2.7 million.

Titanium Machining: A Demanding Production Process

Thanks to its very light weight, high strength and resistance to heat, titanium is a material of choice in the aerospace industry, for example for aircraft structural components which have to withstand temperatures of more than 130 °C and high hydraulic pressures (for example, the hydraulic system pressure on the A380 is 5,000 psi or 345 bar). The production of titanium components is made more difficult not only by the fact that the material is difficult to machine. The complex geometry of the hydraulic valve blocks places great additional demands on the machining technology employed at the Lindenberg machining center. Besides various special tools and tooling machines, cooling lubricants and extremely high-precision processes are necessary. Liebherr-Aerospace has therefore developed the design of the technological systems in a three-year aerospace research project in collaboration with the Institute of Manufacturing Technology of Professor Fritz Klocke at the Laboratory of Machine Tools and Production Engineering (WZL) of the RWTH Aachen University (Germany). In the automation of the machining center, the company was able to benefit from competences within the Liebherr Group. Liebherr-Verzahntechnik GmbH in Kempten (Germany) not only developed the external tool storage and distribution system, it also manufactured the pallet handling system which, amongst other things, supplies the machines with work pieces.

A Leading Company in the Production of Titanium Parts

In recent years, Liebherr-Aerospace Lindenberg GmbH has increasingly developed the machining of titanium components for flight control and actuation systems into one of its core competences, and is now considered to be one of the leading companies in this field. The new machining center will allow the systems supplier to build on this core competence and improve its productivity. Moreover, Liebherr-Aerospace is also contributing to the advanced development of machining technology for geometrically complex components made out of materials which are difficult to machine.

Liebherr-Aerospace is a leading supplier of systems for the aviation industry

Liebherr-Aerospace & Transportation SAS, Toulouse (France), is one of ten divisional control companies within the Liebherr Group and coordinates all activities in the aerospace and transportation systems sectors.

Liebherr-Aerospace is a leading supplier of systems for the aviation industry and has more than five decades of experience in this field. The range of aviation equipment produced by Liebherr for the civil and military sectors includes flight control and actuation systems, landing gear and air management systems. These systems are deployed in wide-bodied aircraft, single aisle and regional aircraft, business jets, combat aircraft, military transporters, military training aircraft, civil helicopters and combat helicopters.

Liebherr's aerospace and transportation systems division employs over 4,000 people. It has four aviation equipment production plants at Lindenberg (Germany), Toulouse (France), Guaratinguetá (Brazil) and Nizhny Novgorod (Russia). These production sites offer a worldwide service with additional customer service centers in Saline (Michigan/USA), Seattle (Washington/USA), Wichita (Kansas/USA), Montreal (Canada), Sao José dos Campos (Brazil), Hamburg (Germany), Moscow (Russia), Dubai (UAE), Singapore and Shanghai (People's Republic of China).

| Contact details from our directory: | |

| Liebherr-Aerospace Lindenberg GmbH | Cabin Pressure Control Systems, Electromechanical Actuators, Hydraulic Systems & Equipment, Pressure Control Valves, Mechanical Actuators, Cabin Heaters, Cooling Systems, Aircraft Landing Gear, Helicopter Landing Gear, Auxiliary Power Units, Hydraulic Actuators, Servoactuators, Hydraulic Filters, Wing Spoilers, Wing Flaps, Aircraft Control Surfaces, Fly-by-Wire Systems, Gearboxes, Control Dampers, Gears & Assemblies, Hydraulic Power Supplies, Air Refuelling Systems, Brake System Components, Aircraft Wheels, Tyres, Steering Systems, Hydraulic Pumps, Automatic Flight Control Systems, Hydraulic System Valves |

| Related aircraft programs: |

| Eurofighter Typhoon |

| Airbus A380 |

| Related directory sectors: |

| Mechanical Components |

| Fluid Power |

| Actuation |

Weekly news by email:

See the latest Bulletin, and sign up free‑of‑charge for future editions.

Textron Systems supports Kaman in advancing Kargo UAV technology

Airbus finalises its acquisition of Aerovel and its UAS Flexrotor

Joby progresses flight test programme

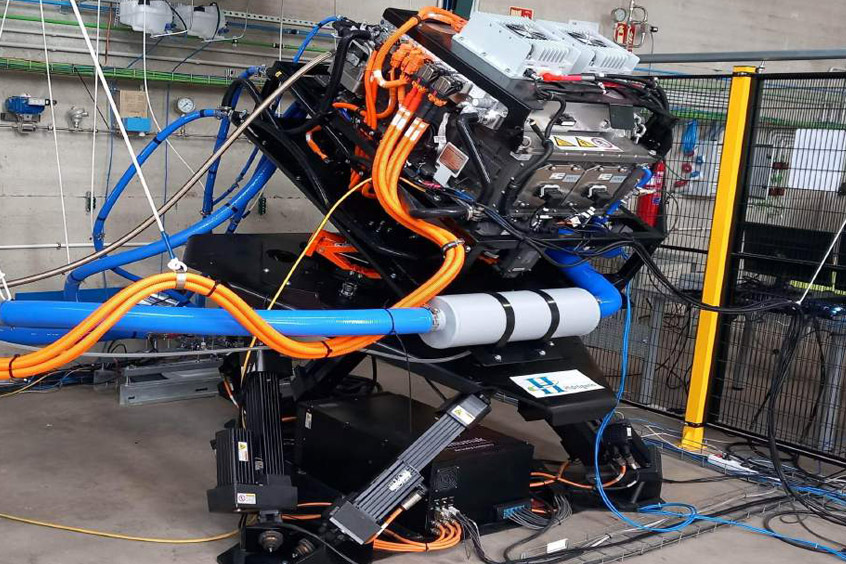

Airbus Upnext sources hydrogen fuel cell for aircraft APU tests