For the first time at JEC Europe 2014, CHOMARAT will present a 1⁄4 scale version of the VX-1 KittyHawkTM. This aircraft, designed by VX AEROSPACE, has a unique shape that is structurally efficient thanks to C-PlyTM, Chomarat's advanced composite reinforcement material.

A unique shape with no wings for a reduced carbon footprint

What makes KittyHawkTM so different from other aircraft is its shape: it has no wings! Indeed, the fuselage and wings are combined into one shape called a 'lifting body' or 'blended wing' aircraft. The shape of the KittyHawk has numerous advantages over traditional designs such as: greater useable internal volume, greater payload capability, better structural efficiency, better durability and better manufacturability. The

construction is thus facilitated as this design will have fewer parts and therefore be easier to assemble. In addition, the aircraft can be scaled to accomodate the intended mission. Manned or unmanned, the VX-1 KittyHawk's massive internal volume is a huge advantage. Furthermore, it will have a smaller footprint than other aircraft when based on payload capability. “The volume will also allow KittyHawk to lead the way in adopting CNG (compressed natural gas) as an aviation fuel. Existing technology CNG tanks fit inside the aircraft with no aerodynamic compromise. At less than 1/3 the cost of avgas, the KittyHawk will have unparalleled operational economy with emissions that are 40% cleaner.” says Bob Skillen, VX Aerospace's CEO.

KittyHawkTM: the first VX Aerospace aircraft manufactured with C-PlyTM

The unique shape of the KittyHawkTM is made structurally efficient with the use of advanced composite reinforcement materials from Chomarat. C-PlyTM (prepregged with Cytec Industries' resin system MTM® 45-1 to create a low density, high damage tolerant prepreg material) is the enabling material for VX Aerospace to use their established hand lay-up and oven curing processes to economically achieve properties similar to autoclave cured UD (uni-directional) prepreg and automatically placed tape prepreg. The C-PlyTM material is durable to handle during lay-up, drapable to accommodate the compound curvatures, and can be manufactured to fully optimize the design relative to fiber angles and ply weights... to ultimately yield a low weight, high performance, and low cost final solution.

“C-PlyTM is the first true advance in carbon fabrics in a long time. It is designed to optimize fiber performance. Chomarat capitalized on the low-angle, thin ply, non-crimp laminate concept developed by Prof. Steve Tsai. The result is a fabric that allows for cost effective production of open mold parts with the same (or better) performance characteristics of ATP parts. This is a game changer for small business." says Bob Skillen.

VX-1 KittyHawkTM: a collaborative work for a game changing aircraft

The VX-1 KittyHawkTM is a game changing aircraft which combines the demonstrated advantages of blended wing aircraft of the past with state of the art design, materials and manufacturing techniques of today. This unique configuration is dynamically stable and aerodynamically efficient. Chomarat and VX Aeropsace have been working together on the project. “Chomarat and VX Aerospace have developed a close working relationship, where Chomarat provides enabling material and VX provides important commercial feedback and testing that has helped define our directional priorities in the development of C-Ply.” says Brian Laufenberg, President of Chomarat North America.

Flight testing will begin next month.

| Contact details from our directory: | |

| Chomarat Group | Carbon-reinforced Composites |

| VX Aerospace Corporation | Aircraft Structural Components, Composite Manufacturing Services, Prepreg, Prototyping, Tooling, Composite Moulding |

| Related directory sectors: |

| Composites |

Weekly news by email:

See the latest Bulletin, and sign up free‑of‑charge for future editions.

Textron Systems supports Kaman in advancing Kargo UAV technology

Airbus finalises its acquisition of Aerovel and its UAS Flexrotor

Joby progresses flight test programme

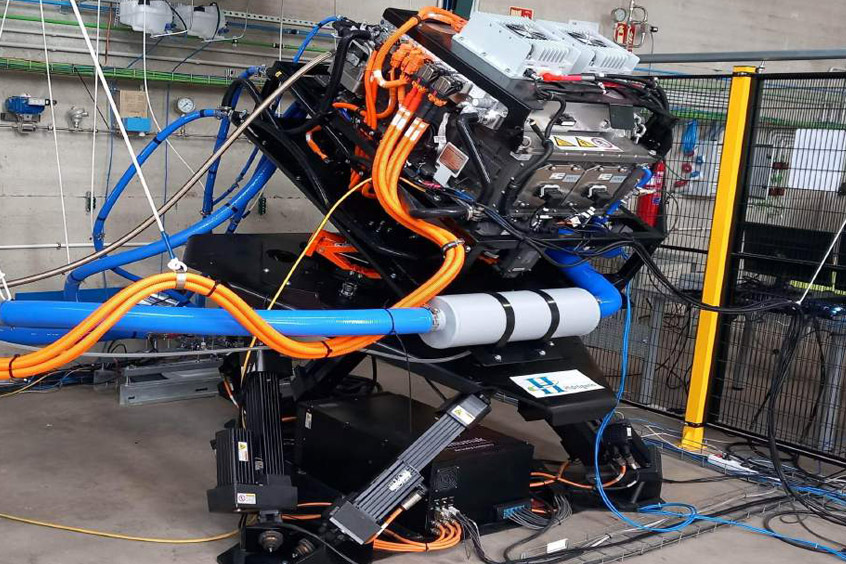

Airbus Upnext sources hydrogen fuel cell for aircraft APU tests