Turbine Air Corporation selected GE Aviation's H75 turboprop engine to power its new Turbine Venom aircraft.

The Turbine Venom is an aircraft manufactured on an approved FAA kit build status. The Turbine Venom is the next-generation version of the Turbine Legend, which began production in 1998.

Produced entirely of carbon fiber and graphite, the Turbine Venom takes advantage of superior strength and light-weight materials to achieve a projected speed of 350 knots true airspeed (TAS) and a climb rate exceeding 6000 feet per minute. The aircraft will come standard with a full Garmin suite of Avionics and 140 gallons of fuel giving it a 1,100 nautical mile range.

The GE H75 engine was selected by Turbine Air Corporation to power the Turbine Legend because of its extremely robust design, along with a 4000 hour time between overhaul (TBO), no hot section requirement and zero fuel nozzle maintenance.

“The combination of the 750 HP GE turboprop and a 2,200 pound empty weight will produce dramatic performance and agility,” said Turbine Air Corporation President Robert Metzler. “This not only gives our customers all the performance they demand, but it also reduces their cost of ownership and operation, a true winning combination.”

“GE Aviation is proud to be selected by Turbine Air for their new Turbine Venom aircraft application,” said Norman Baker, President & Managing Executive of GE's Business & General Aviation Turboprops. “GE Aviation stands ready to fully support our H Series customers with an expanded service network and customer training classes to ensure a smooth entry into service experience.”

The H Series turboprop family incorporates GE's 3-D aerodynamic design techniques and advanced materials to create a powerful, fuel-efficient, durable engine with no recurrent fuel nozzle inspections and no hot section inspection for a multitude of uses: agricultural, business turboprops, commuter and utility aircraft. GE is also developing an integrated electronic engine control (EEC) for true single lever power control, and full auto-start capability to help ease pilot workload for H Series-powered aircraft. Certification of the EEC is expected shortly with the first application being the Nextant G90XT.

All versions of the Turbine Venom, from fast build kits with Build Center Assistance to completed aircraft for commercial and military markets, will be exclusively powered by the GE H75.

| Contact details from our directory: | |

| GE Aerospace Business & General Aviation Turboprops | Turboprop Engines |

| Related directory sectors: |

| Engines |

Weekly news by email:

See the latest Bulletin, and sign up free‑of‑charge for future editions.

Textron Systems supports Kaman in advancing Kargo UAV technology

Airbus finalises its acquisition of Aerovel and its UAS Flexrotor

Joby progresses flight test programme

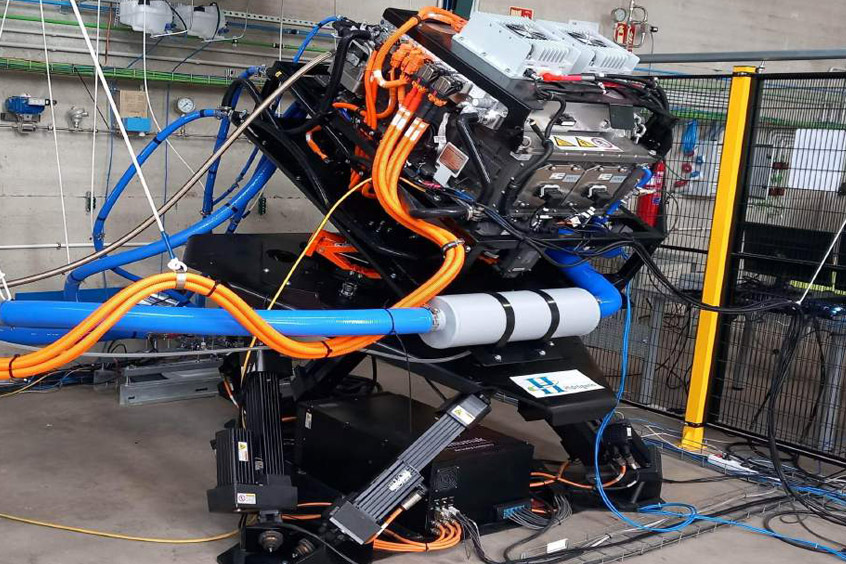

Airbus Upnext sources hydrogen fuel cell for aircraft APU tests