Parsifal, coordinated by the University of Pisa, is a research project which has received three million euros in funds from the European Union to develop the PrandtlPlane (PrP), an innovative aircraft capable of facilitating the air transport of the future.

The project has received 3 million euros in funds from the EU and has been awarded the first university grant from the BIHO competition. The name pays homage to the German physicist and father of aerodynamics, Ludwig Prandtl. “The challenge facing the commercial aviation of the future lies in finding aircraft with a limited wingspan which are more spacious and efficient than those actually in use,“ explains Professor Aldo Frediani, coordinator of Parsifal. “The main objective of our project is to design an aircraft with the same wingspan as an Airbus A320 or Boeing B737 and which has the same cargo capacity as an aircraft of a superior category, such as an Airbus 330 or a Boeing 767, and the fuel consumption of the smaller aircraft. All of this thanks to the PrP wing configuration.”

The Parsifal project, the acronym of “Prandtlplane ARchitecture for the Sustainable Improvement of Future AirpLane”, will help to implement the scientific, technological and engineering background needed to design these innovative, new generation aircraft . As well as PrandtlPlane (PrP), the configurations which are candidates for the aviation of the future are Blended Wing Body (BWB) and Truss Braced Wings (TBW). These all present advantages and disadvantages, but as has already been seen, only the PrP configuration allows for the design of aircraft with limited wingspan, high load capacity and maximum efficiency: the PrP configuration presents the least induced resistance of all the load-bearing structures with the same weight and wingspan.

“Over the next twenty years the number of air passengers is expected to double while only a limited expansion of airport territory will be possible especially in Europe,” adds Frediani.

“Among the challenges we aim to face in our study, is the designing of an aircraft which can satisfy the increasing amount of passenger traffic and at the same time drastically reduce noise and harmful emissions while increasing safety and comfort in flight. We will demonstrate that the PrP configuration is flexible and may be used for both the transport of passengers and cargo in a wide range of missions.”

A further aim of the Parsifal project is to develop methods to look into the possibility of applying the Prp configuration to aircraft of all dimensions and load capacity. This also includes the Ultralarge which is much larger than the Airbus A380 and is the aircraft with the largest dimensions (80x80 metres) capable of landing in civilian airports.

The other PARSIFAL partners are SkyBox Engineering, a spin off of the University of Pisa, Onera from Paris (France), DLR from Hamburg (Germany), University of Delft (Holland) and ENSAM fromi Bordeaux (France). As well as Aldo Fredian, the other researchers from Pisa involved in the project come from the University of Pisa and SkyBox Engineering, a spin-off of the University. For the University the professors involved are Aldo Frediani, Mario Chiarelli, Maria Vittoria Salvetti, Simone Camarri, Alessandro Quarta, Daniele Fanteria and Gianpietro Di Rito from the Department of Civil and Industrial Engineering, Aerospace Division, and the professors Giovanna Mariani and Riccardo Giannetti from the Department of Economics and Management. For SkyBox Engineering the participants are Vittorio Cipolla, Vincenzo Binante and Emanuele Rizzo.

| Contact details from our directory: | |

| Universita di Pisa | Research/Consulting Services, Academic Institutions |

| Related directory sectors: |

| Design |

Weekly news by email:

See the latest Bulletin, and sign up free‑of‑charge for future editions.

Textron Systems supports Kaman in advancing Kargo UAV technology

Airbus finalises its acquisition of Aerovel and its UAS Flexrotor

Joby progresses flight test programme

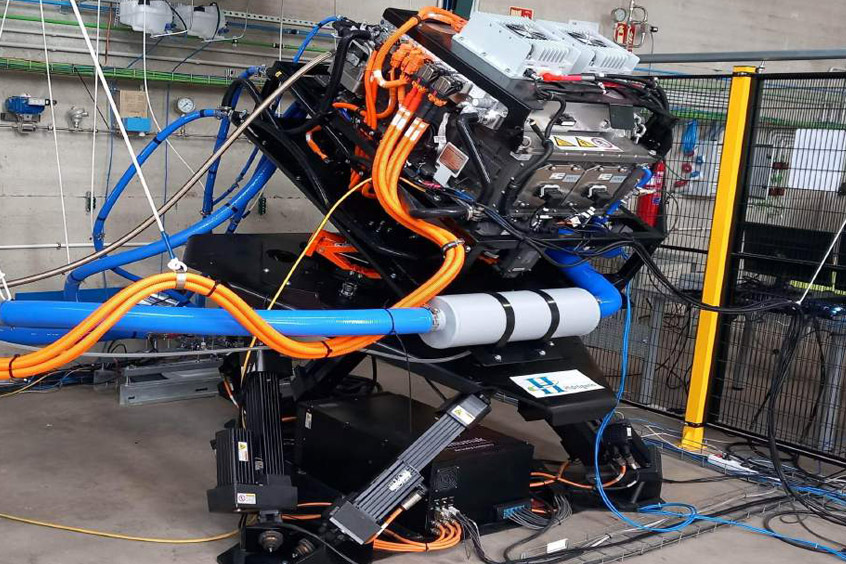

Airbus Upnext sources hydrogen fuel cell for aircraft APU tests